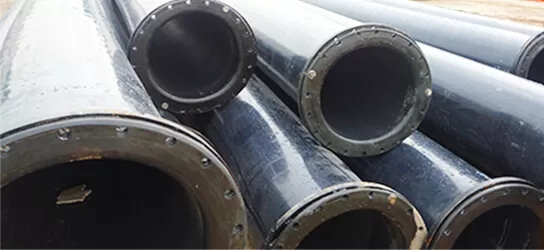

UHMWPE pipe is a high molecular weight polyethylene high wear resistant pipeline with molecular weight larger than 2 million 500 thousand, including polymer high abrasion elbow, wear-resistant three links and four links.

The compressive strength of ultra-high molecular weight polyethylene pipe is 2.5 times of PE80, PEl00 is 2 times, the ability of resisting environmental stress cracking is 5 times of PE100, and fatigue resistance is 30 times of PE100.

The friction coefficient of ultra-high molecular weight polyethylene pipe is only 0.07-0.11, and its molecular chain is very long. The wear resistance of pipes is 4-7 times higher than that of steel tubes and metal pipes, which is 10 times that of PE100.

In many pipe materials, the wear index is the smallest. The wear resistance is 4-7 times higher than that of steel pipe and stainless steel tube, more than 10 times higher than that of PVC pipe and polyethylene pipe, which greatly improves the service life of the pipe.

Ultra high molecular weight polyethylene pipe material is difficult to crush and form for two times after molding. Therefore, ultra high molecular weight polyethylene pipe is produced by new raw material, and no recycling material can be added to ensure the sanitation of pipeline system. And many of the common PE, PVC and other pipe manufacturers (even the national exemption products) added the recycled materials to reduce the cost.

Leader Dredger supply the best pipeline for customer.

Product Parameter Comparison

| Project | Unit | Ultrahigh molecular weight

polyethlene tube | Q235Steel pipe | PE tube |

|---|

| Density | G/cm³ | 0.96 | 7.85 | 0.93 |

| Average Molecular weight | 10*4 | 250 | - | 15-30 |

| Yield stress stress | Mpa | 22 | 126 | 11 |

| Tensile stength | Mpa | 40 | 235 | 24 |

| Elongation at break | % | 400 | 25 | 300 |

| Impact strength | Kj/m² | 110 | 60 | 20 |

| Friction coefficient | - | 0.07-0.11 | 0.32-0.45 | 0.32-0.44 |

| Abrasion of mortar | % | 0.3 | 1.82 | 3.45 |

| Low temperature resistance | 0C | -100 | -30 | -70 |

Brief introduction of UHMWPE Pipe

Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 2 million viscosity-average molecular weight,under the polymerization of ethylene, butadiene monomer in the catalyst. Ultra-high molecular weight polyethylene pipe has the superior performance such as very high wear resistance, impact resistance, excellent resistance to internal pressure strength, resistance to environmental stress cracking, eminent self-lubricating, anti-adhesion, the unique low temperature resistance, good chemical tability , easy installation and so on, and it is widely used in metallurgical mines, electric power, petroleum, natural gas, textiles, paper making, food, chemical industry, machinery, electrical and other industries.

Advantage

1.Long lifespan,more than 12 years under normal condition.

2.Good corrosion resistance.

3.Good crack growth resistance.

4.Little coefficient of friction and low flow resistance.

5.Excellent wear resistence, its wear restistance is 8 times higher than steel pipes under normal conditons.

6.Good solder ability,its interface strength is higher than the pipe body.

7.Good flexibility and anti-scratch ability.

8.Very high impact resistance.

9. The unique resistance to low temperature, workable at temperature - 40-60 ° c.

10. Light weight, 1/8 weight of steel pipe, easy for transportation and installation.

11. Flexible metal flange for connection, easy for installation and disassembly.

12. Smooth inner wall, easy for pipeline transportation.

| Inside Diameter | Wall Thickness |

|---|

| DN(mm) | 0.6Mpa | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6Mpa | 2.0Mpa |

| 150 | - | - | 7 | 8 | 11 | 14 |

| 178 | - | - | 8 | 10 | 13 | 16 |

| 194 | - | 7 | 8 | 11 | 14 | 18 |

| 200 | - | 7 | 9 | 11 | 14 | 18 |

| 219 | - | 8 | 10 | 12 | 16 | 20 |

| 245 | - | 8 | 11 | 13 | 18 | 22 |

| 250 | 7 | 9 | 11 | 14 | 18 | 23 |

| 273 | 7 | 9 | 12 | 15 | 20 | 25 |

| 300 | 8 | 10 | 13 | 17 | 23 | 30 |

| 325 | 8 | 11 | 14 | 18 | 23 | 30 |

| 350 | 9 | 12 | 15 | 19 | 25 | 32 |

| 400 | 10 | 14 | 17 | 22 | 29 | 36 |

| 450 | 12 | 16 | 20 | 25 | 32 | 41 |

| 500 | 13 | 17 | 22 | 27 | 36 | 45 |

| 550 | 14 | 19 | 24 | 30 | 39 | 50 |

| 600 | 15 | 21 | 26 | 33 | 43 | - |

| 610 | 16 | 21 | 27 | 34 | 44 | - |

| 650 | 17 | 22 | 28 | 36 | 46 | - |

| 660 | 17 | 23 | 29 | 36 | 47 | - |

| 700 | 18 | 24 | 30 | 38 | 50 | - |

| 710 | 18 | 24 | 31 | 39 | - | - |

| 750 | 19 | 26 | 33 | 41 | - | - |

| 800 | 21 | 28 | 35 | 44 | - | - |

| 850 | 22 | 29 | 37 | 47 | - | - |

| 900 | 23 | 31 | 39 | 49 | - | - |

| 1000 | 26 | 34 | 43 | - | - | - |

| 1100 | 28 | 38 | 48 | - | - | - |

| 1200 | 31 | 41 | - | - | - | - |

INTERESTED IN OUR DREDGERS?

Call us or fill out the form below and one of our experts

will advise you on the best solutions for your project