CUTTER SUCTION DREDGER INTRODUCTION:

Hull without propulsion means / optional with propulsion equipment (small size can also meet propulsion)

Self-propelled, specially designed ocean-going hull

No matter whether the cutter suction dredger can self-propell, it needs to fix the position with a positioning pile before it can start work.A cutter head is a mechanical rotating tool that can cut hard soil or rock into pieces. The winch pulls the winch by pulling the winch to make a fan-shaped movement, and the rotating cutter head can enter the water and swing in the soil. It is installed in front of the suction head, and the soil and rock cut into fragments are sent directly to the mud treatment area through the powerful suction of the dredging pump.

For specific types of soil, Leader Dredger will design different cutter head heads. Because different soils have different hardness and different viscosities, the cutter head heads that need to be used will be different.

It should be noted that the cutter teeth need to be replaced, because dredging in hard soil will cause it to wear out.

The cutter suction dredger equipped with propulsion means can carry out long-distance travel and is used flexibly all over the world.

Small and medium-sized cutter suction dredgers can be disassembled and transported on land.

It should be noted that the cutter suction dredger is very sensitive to the rough seas, because the turbulent waves will break the positioning device of the cutter suction dredger, and make the cutter head off the bottom of the water, causing additional losses. Use the three anchor positioning method.

It needs to be equipped with a positioning device during work, which is suitable for the still and slightly wavy river surface, because the positioning device of the cutter suction dredger needs to be inserted into the soil, and the excessive surge will bend the positioning device of the dredger.

Cutter suction dredgers have high productivity and can effectively handle most of the materials.

Material type:

Small and medium-sized cutter suction dredger:

Silt

Clay

Sand

Gravel

Large cutter suction dredger:

Coral

Broken rock

Small hard stones

Cutter suction dredgers can be used in many environments, such as river dredging, channel dredging, port construction and maintenance, and environmental dredging.

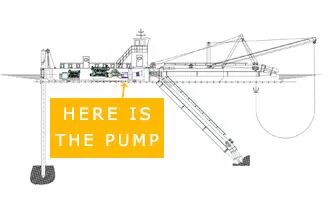

INBOARD PUMP DREDGER

When the depth of most working conditions is relatively shallow, discharge distance is relatively close, the preference is INBOARD PUMP CUTTER SUCTION DREDGER

Inboard pump dredger is the most common type of cutter suction dredger, and it is currently the most cost-effective model. Its pump is installed in the engine room. Because the driving structure of the pump is relatively simple, it can save costs. This design is suitable for most waters and is the most common among small and medium dredgers.

1. Pump inside the engine room

2. Normal-size Dredger body

3. Normal-length Ladder

4. Normal-size Cutter

5. Normal mixture density(normal 20%)

6. One deck crane

7. Simple drive : main engine drives the pump through the gerbox

Features:

One Pump

Digging depth: 2-15m

discharge distance of single pump: 1-2.5Km

Working Condition:

The cutter head is suitable for most working conditions.

Application:

River dredging, pond dredging, lake dredging

Related Products

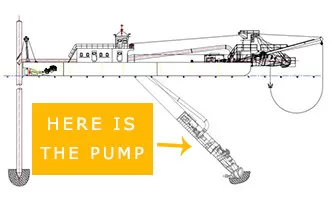

SUBMERSIBLE PUMP DREDGER

When the depth of most working conditions is relatively shallow, discharge distance relatively close, the priority is to choose the SUBMERSIBLE PUMP CUTTER SUCTION DREDGER, that is, the pump is on the ladder.

The pump of the dredger is on the ladder. Compared with inboard pump dredger, the suction port of the pump is closer to the sediment at the bottom of the river, making the pump suction concentration higher. It achieves higher output and higher productivity. Submersible pump dredger has deeper digging depth and higher concentration than Inboard pump dredger.

Because the submersible pump dredger can dig deep to 30m underwater, a larger hull is required. Pumps, drives, and motors all need to be installed on higher-strength ladders and more complex driving methods, resulting in submersible pump dredger cost much higher than Inboard pump dredger.

1. Pump in the front part of the ladder & near the cutter

2. Large-size Dredger body

3. Long Ladder

4. Large Cutter

5. Higher mixture density(30% or more)

6. Two deck cranes

7. The generator set starts the electric motor through frequency converter, then the motor drives the pump

Features:

Digging depth: up to 30m (does not affect the output at the depth)

discharge distance: 1-2.5Km

Submersible Pump Dredger Advantages:

Concentration and output: one to three times the inboard pump dredger

Application:

Deeper waters (same as inboard pump dredger)

Related Products

DUAL PUMP DREDGER

When the water depth is very deep and the discharge distance is very far, suitable for DUAL PUMP, or even MULTI-PUMP CUTTER SUCTION DREDGER

The Dual Pump Dredger has two pumps, a main pump on the ladder, and another relay pump in the engine room. This design can achieve large digging depth and output and ultra-long distance.

Dual pump dredger is the ideal choice for maximum digging depth and very long discharge distance.

1. Dual Pump, one in the front part of the ladder & near the cutter another on deck or engine room

2. Long discharge distance design

3. Large-size Dredger body

4. Long Ladder

5. Large Cutter

6. Higher mixture density(30% or more)

7. Two deck cranes

8. More advanced dredging systems

Features:

Digging depth: up to 30m (does not affect the output at the depth)

discharge distance: >5Km

Daul Pump Dredger Advantages:

Concentration and output: one to three times the inboard pump dredger

Application:

Channel maintenance, Port construction, Island reef construction

Related Products