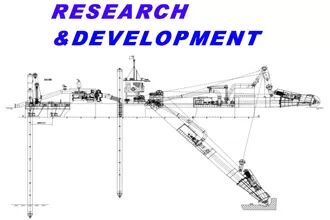

Modular Technology Of Dredger

Catalog

Leader Dredger has been highly evaluated in the field of dredger modular technology, and its modular design capability has become a new technology that the industry is competing for development and application. For small dredgers, modularization is not only conducive to the complete function of the cabin and the disassembly and assembly of each unit, but also shortens the adjustment cycle and reduces transportation costs.

1. The concept of modular technology for dredgers

The module is a standardized integrated unit with independence, integrity and combination. Modularization usually has two meanings: the formation of modules and the construction of systems with modules, the decomposition of modules and the combination of modules. The modularization of the small dredger is based on its layout and working characteristics, uniting the main hull, deckhouse and working mechanism to achieve a certain independence of each unit and the convenience of disassembly and assembly, thereby shortening the construction and adjustment cycle , Improve the applicability and economy of ships.

2. Division of module units

It consists of the main hull, deckhouse and corresponding working institutions.

1. The principle of division

According to the requirements of the design specification, the ship must not only set up the excavation system, the suction and discharge system, the positioning pile system and the anchoring system, but also ensure the transportation of the railway and the road, that is, the size and weight of the module unit of the ship should meet the freight of the railway and the road. Transportation requirements.

Rail transportation has stricter requirements than roads. For railway transportation, its cargo transportation is divided into normal transportation, first-level over-limit, second-level over-limit and special-grade transportation. The higher the overrun level, the slower the adjustment speed and the more expensive the freight. In addition, the length of an ordinary flatbed truck is 13000mm (both ends can exceed 20mm), and the maximum load-bearing capacity is 60t. Therefore, the division of modular units should not only consider the economics of transportation, so that the unit weight and size should be controlled within the normal transportation range of train goods, but also the independence and integrity of each unit should be considered as much as possible to reduce the labor intensity of disassembly and assembly.

2. Elements of a modular unit

According to the principle of division, in addition to the working system, the ship is divided into main pontoons (including engine room shed), front pontoons (2), rear pontoons (2), crew living units, and control room units.

3. Splicing of modular units

1. Module unit connection type

The main hull of the ship is assembled by pontoons. Considering the convenience and economy of disassembly and assembly, between the main pontoon and side pontoons, the deck is connected by high-strength bolts through ear plates, the bottom of the ship is in the form of wedge-shaped hooks, and bolts are used between the living unit and the main pontoon and control room connection.

4. Hoisting of the module unit

For the assembled dredger, whether it is dismantling, assembling, or during transportation, the hoisting of each module unit is essential. In view of the different weight and size of each module unit, the type and arrangement of the lifting lugs are also different. The main pontoon unit is heavy and has a large opening on the deck, so in addition to choosing heavy lugs, It should be noted that the position of the ear plate should be on the strong frame. For other lighter modular units, the lifting lugs can be combined with the connecting eye plate.