There are 32 people in the technology and design department

12 senior technicians

20 technicians.

Can design and have all kinds of dredgers, civil, warships, marine engineering equipment qualifications.

We can do different types of China Classification Society CCS, American ABS, European BV, Italian RINA standard ships, dredgers, ships, etc.

The design of the cutter suction dredger involves disciplines such as mechanical manufacturing, electrical and electronic, hydrodynamics, computer technology, automation science, materials science, marine meteorology and even nuclear physics, and belongs to the category of system engineering design.

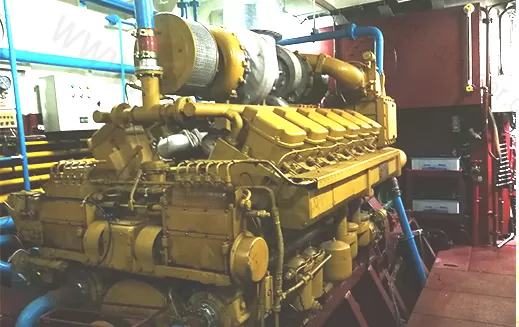

Leader Dredger specializes in analysis and design of dredger hull size, winch bridge, winch system, hydraulic system, positioning pile, mud pump system and its professional design, And repeatedly debug the power system, environment, vibration and noise issues

According to the dredging volume, digging depth index and soil quality of the construction project, the specific performance indexes such as the digging depth, soil breaking capacity and production capacity of the cutter suction dredger are determined.

This design concept is not only widely used in general commercial dredging fields, but also in military, scientific research and engineering fields.

The difference is that dredgers that serve commercial projects can improve the performance of cutter suction dredgers to achieve higher production efficiency and economic benefits, while dredgers used in military and scientific research fields can meet the needs of specific projects. Its economic performance is relatively lower.

In the current economic and social environment, a design that only focuses on technical performance without considering product economic indicators is almost impossible. The cutter suction dredger design is also based on practicality, reliability and other technical indicators, fully considering the economic performance in use, and weighing the unified indicators of technical performance and economic performance to achieve better design results.

For more details, please visit -Technical innovation of Leader Dredger